FORENSIC ENGINEERING

Our capabilities and services cover the entire range of forensic engineering which includes industrial inspections, data collection and analysis, lab tests to determine the cause of failure, and technical report to provide the rootcasue analysis, corrective actions and liability

Why Choose Our Service

We specialize in consulting in choosing and actually installing doing the of both full-cycle batteries.

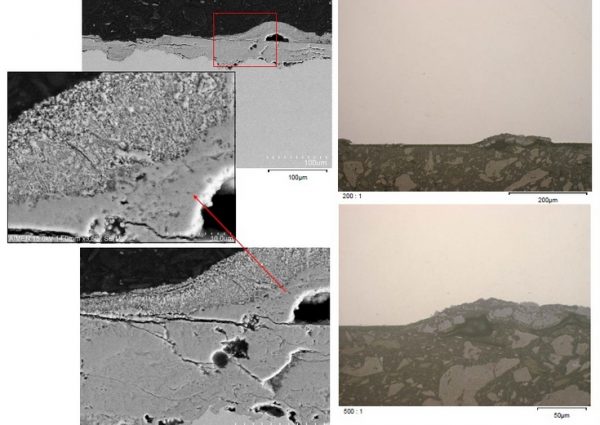

We are capable of determining the root cause of any chemical and/or mechanical problems in the plant, related to fracture, creep corrosion, fatigue, wear, deformation, chemical contamination, sampling, corrosion control, chemical treatment program, materials evaluation, among other.

In our metallurgical lab we can perform:

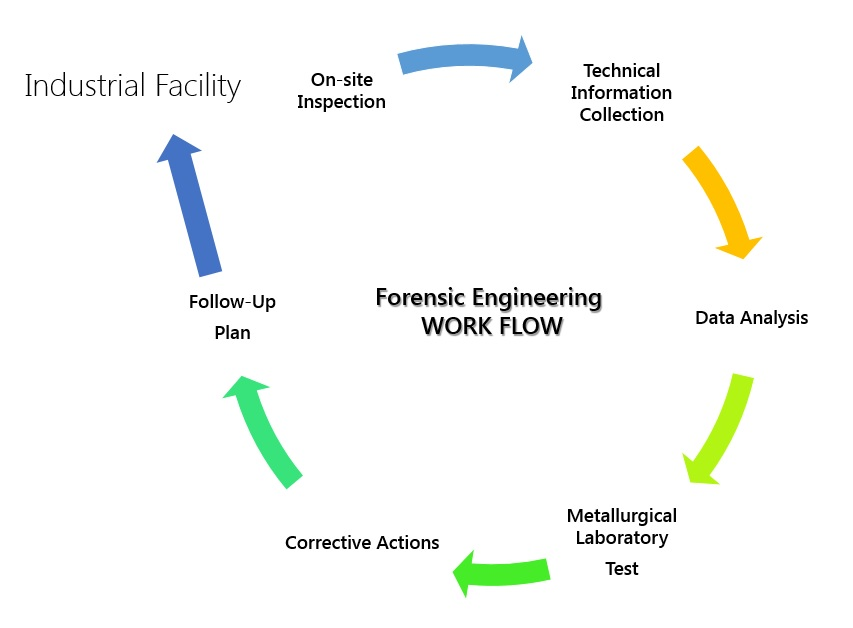

WORK FLOW

We perform any forensic engineering assignment based on a continuous maintenance methodology to enhance the synergy with the performance of the plant where we monitor some key parameters that will provide the required information a right for risk assessment.